MVM-EGI’s CIRCUMIXTM hydrodynamic mixer has been developed for the large-scale, continuous production of powder-liquid mixtures. Its patented working method relies on the momentum of flow, hydrodynamic forces, turbulency of the liquid and optimized residence time to produce highly homogenous mixtures rather than mechanical agitation.

CIRCUMIXTM is available for a wide range of capacity requirements, its rated capacity ranging between 20 and 300 m3/h of continuous mixture production. The density and therefore the concentration of the produced mixture is continuously metered and can be accurately controlled. The mixer can cope with both Newtonian and Bingham-plastic fluids.

CIRCUMIXTM offers multiple advantages over traditional, mechanically agitated mixers:

- Due to its specially designed shape and working method all the fluid is kept in constant, vigorous motion, there no “dead” zones where particles could settle: the homogeneity of the produced mixture is unusually high.

- With no mechanical agitation and hardly any moving parts, the construction is simple, the equipment is highly reliable, easy to maintain, wear and tear is minimized.

- The continuous operation makes it an ideal candidate for different mixing tasks in the process industries.

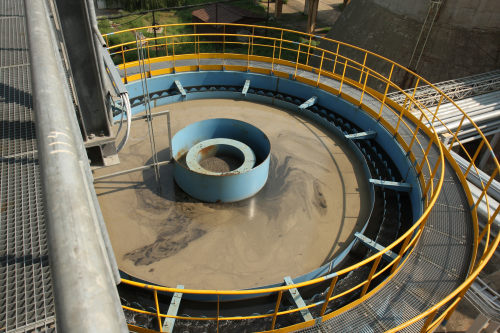

3D model of a CircumixTM mixer

Pre-assembled CircumixTM mixer(s) in the workshop before shipment.